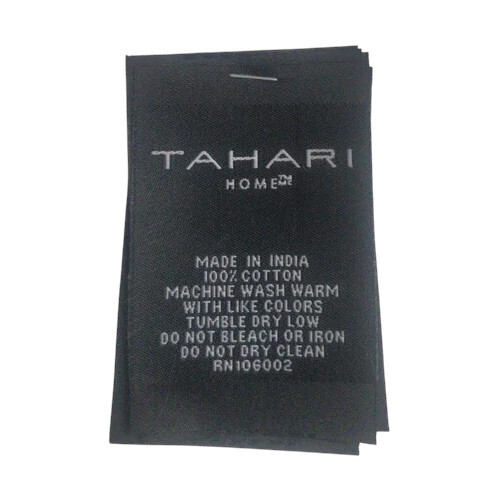

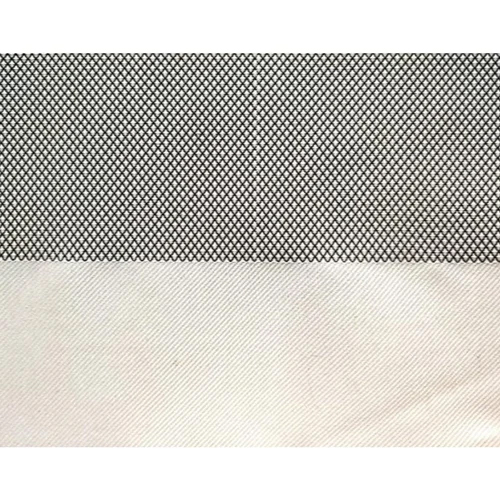

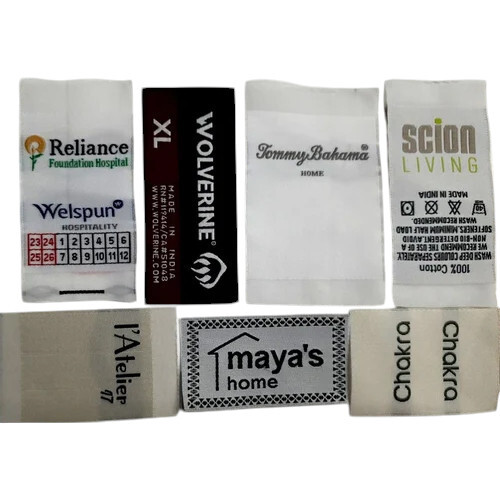

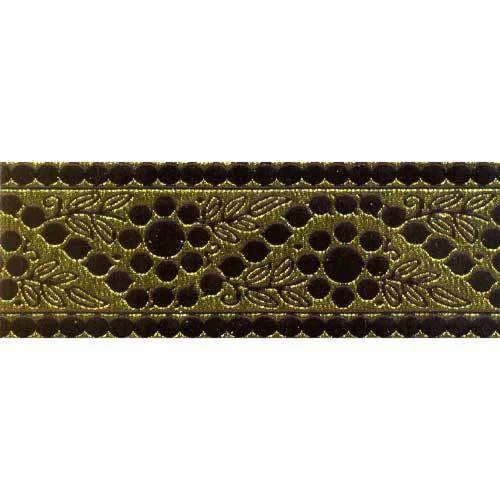

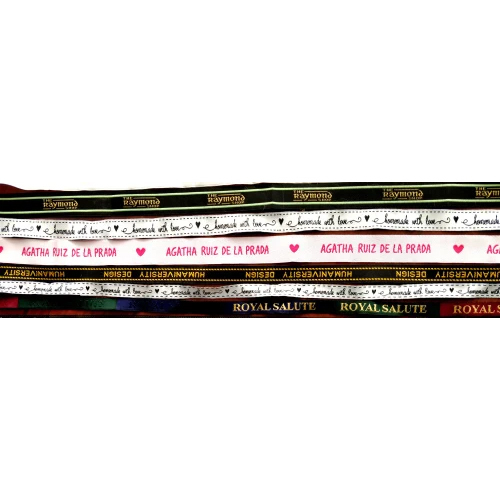

Reliable and Affordable Polyester Woven Labels, Polyester Tube Label, Taffeta Woven Label,

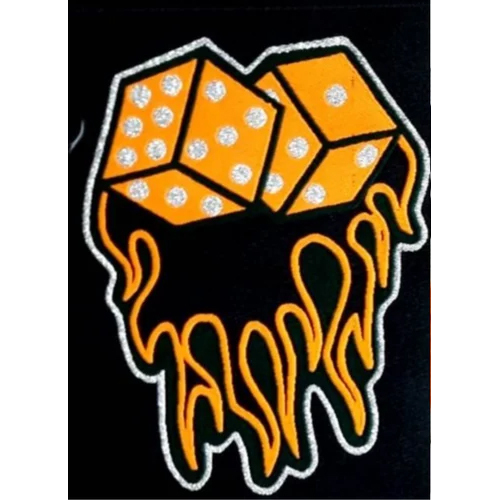

Damask Polyester Woven Label, Polyester Woven Tape Laces, Printed Woven

Patch, etc.

Founded in the year 1985, Kishore Labels Pvt. Ltd. has emerged as a

leading name in the field of label and lace manufacturing. With over

four decades of dedicated service, we have established ourselves as a

trusted manufacturer and supplier of an extensive range of high-quality

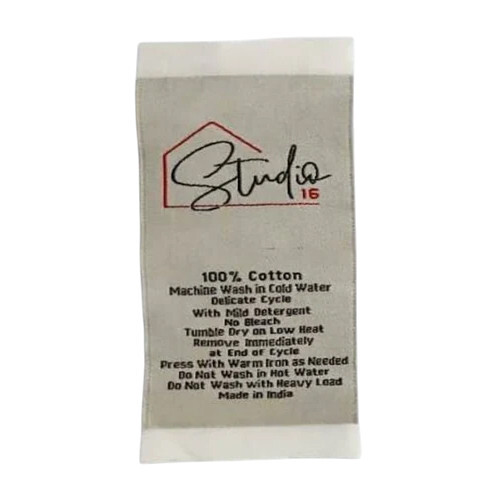

products including Polyester Woven Labels, Polyester Tube Label, Taffeta Woven Label,

Damask Polyester Woven Label, Polyester Woven Tape Laces, Printed Woven

Patch, etc. Our journey, marked by consistency and innovation,

has been built on a strong foundation of quality, creativity, and

customer satisfaction. Every product we deliver is a reflection of our

commitment to excellence and is made using superior raw materials such

as skin-friendly fabrics and premium threads, ensuring durability,

comfort, and visual appeal.

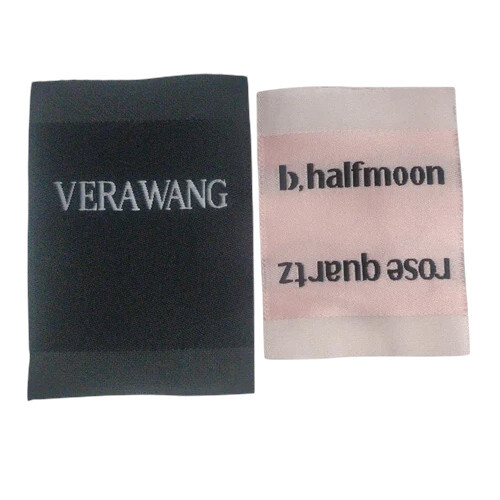

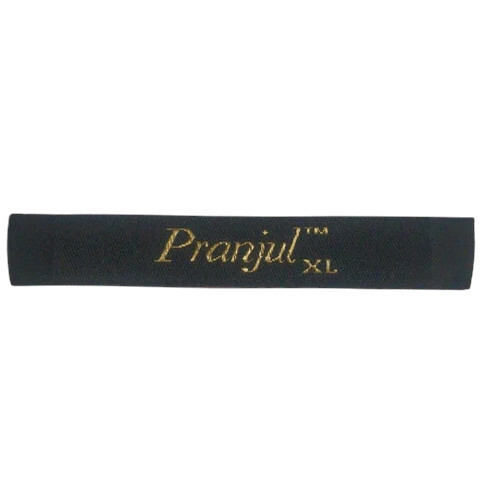

We use state-of-the-art rapier looms and advanced MEI machines imported from Italy to ensure flawless weaving, sharp detailing, and superior finish. Our advanced textile engineering capabilities allow us to deliver highly customized, precise, and creative label solutions in up to eight colors, offering vast possibilities for backgrounds, patterns, and lettering.

Infrastructure & Technology

At Kishore Labels, we operate from a well-equipped production unit powered by latest machinery, a skilled workforce, and strong technical leadership. Our infrastructure combines traditional craftsmanship with cutting-edge automation, ensuring efficient, scalable, and quality-driven production.

Our engineering department determines the most effective weaving techniques and visual presentation to match the branding goals of our clients. Be it mass production or low-volume customized batches, we are capable of handling any volume without compromising on quality or delivery timelines.

Quality Assurance

We are a quality-focused organization and believe that product excellence begins at the raw material stage. We source premium threads and fabrics from reliable vendors and incorporate rigorous quality checks throughout our production process.

Each label or lace we produce undergoes strict quality control in our dedicated in-house lab, where we test for:

These stringent checks ensure that only defect-free, industry-standard products reach our clients.

Our Team

Behind our success is a team of highly experienced professionals in weaving, stitching, embroidery, design, and management. Our selection process for employees is meticulous, involving written tests, interviews, and domain-specific assessments. Once onboarded, we provide modern tools, machinery, and ongoing training, including soft-skill and technical upskilling workshops.

Our teams dedication and craftsmanship help us deliver excellence in every product while meeting tight deadlines and diverse design requirements.

Client-Centric Approaches

We value our clients and strive to build lasting relationships based on trust, transparency, and satisfaction. Every product is crafted with the end-user in mind whether its a soft satin label for a baby garment or a bold patch for denim jackets, we ensure comfort, durability, and brand appeal.

Our client servicing team works closely with each customer, capturing their specific needs and providing regular updates throughout the production process. We welcome feedback and have built internal systems to incorporate customer suggestions into our development cycle quickly and efficiently.

We use state-of-the-art rapier looms and advanced MEI machines imported from Italy to ensure flawless weaving, sharp detailing, and superior finish. Our advanced textile engineering capabilities allow us to deliver highly customized, precise, and creative label solutions in up to eight colors, offering vast possibilities for backgrounds, patterns, and lettering.

Infrastructure & Technology

At Kishore Labels, we operate from a well-equipped production unit powered by latest machinery, a skilled workforce, and strong technical leadership. Our infrastructure combines traditional craftsmanship with cutting-edge automation, ensuring efficient, scalable, and quality-driven production.

Our engineering department determines the most effective weaving techniques and visual presentation to match the branding goals of our clients. Be it mass production or low-volume customized batches, we are capable of handling any volume without compromising on quality or delivery timelines.

Quality Assurance

We are a quality-focused organization and believe that product excellence begins at the raw material stage. We source premium threads and fabrics from reliable vendors and incorporate rigorous quality checks throughout our production process.

Each label or lace we produce undergoes strict quality control in our dedicated in-house lab, where we test for:

- Stitch quality

- Design clarity and alignment

- Colorfastness

- Fabric softness and skin-friendliness

- Durability and wash resistance

- Finishing and cut precision

These stringent checks ensure that only defect-free, industry-standard products reach our clients.

Our Team

Behind our success is a team of highly experienced professionals in weaving, stitching, embroidery, design, and management. Our selection process for employees is meticulous, involving written tests, interviews, and domain-specific assessments. Once onboarded, we provide modern tools, machinery, and ongoing training, including soft-skill and technical upskilling workshops.

Our teams dedication and craftsmanship help us deliver excellence in every product while meeting tight deadlines and diverse design requirements.

Client-Centric Approaches

We value our clients and strive to build lasting relationships based on trust, transparency, and satisfaction. Every product is crafted with the end-user in mind whether its a soft satin label for a baby garment or a bold patch for denim jackets, we ensure comfort, durability, and brand appeal.

Our client servicing team works closely with each customer, capturing their specific needs and providing regular updates throughout the production process. We welcome feedback and have built internal systems to incorporate customer suggestions into our development cycle quickly and efficiently.

We accept bulk orders only.